Note

Go to the end to download the full example code.

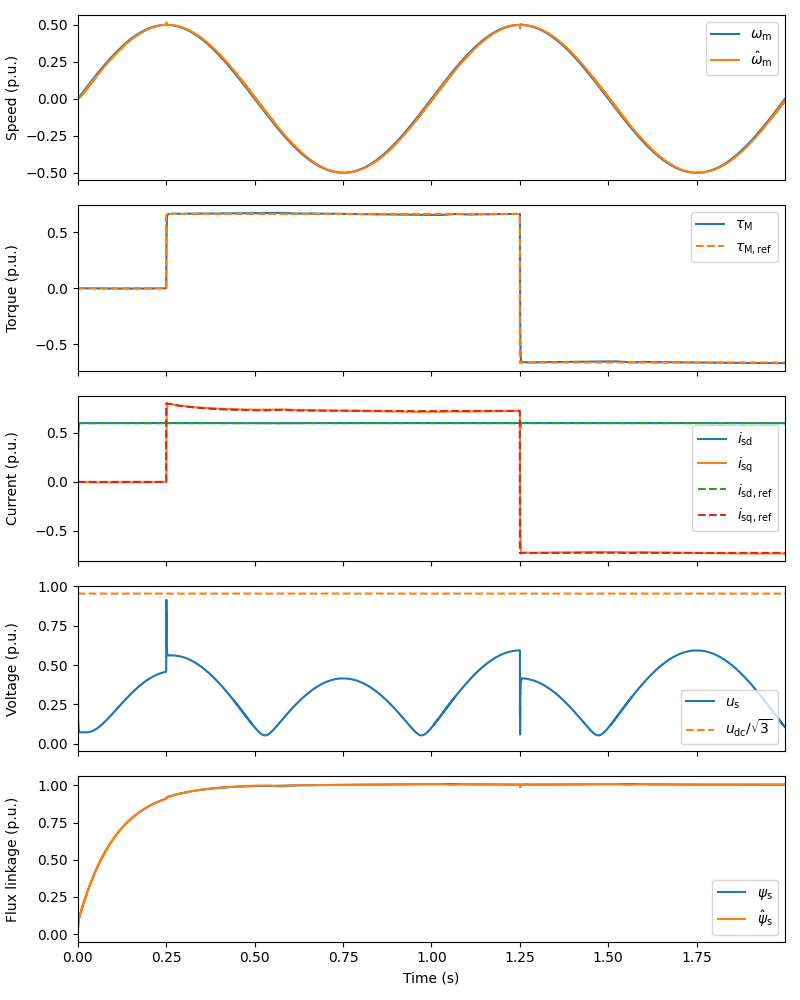

2.2-kW induction motor, torque-control mode#

This example simulates current-vector control of a 2.2-kW induction motor drive in torque-control mode.

import numpy as np

from motulator.drive import model

import motulator.drive.control.im as control

from motulator.drive.utils import (

BaseValues, NominalValues, plot, InductionMachinePars,

InductionMachineInvGammaPars)

Compute base values based on the nominal values (just for figures).

nom = NominalValues(U=400, I=5, f=50, P=2.2e3, tau=14.6)

base = BaseValues.from_nominal(nom, n_p=2)

Configure the system model.

# Parametrize the machine model using its inverse-Γ parameters

par = InductionMachineInvGammaPars(

n_p=2, R_s=3.7, R_R=2.1, L_sgm=.021, L_M=.224)

mdl_par = InductionMachinePars.from_inv_gamma_model_pars(par)

machine = model.InductionMachine(mdl_par)

# Use externally specified actual speed w_M(t), defined subsequently below

mechanics = model.ExternalRotorSpeed()

converter = model.VoltageSourceConverter(u_dc=540)

mdl = model.Drive(converter, machine, mechanics)

Configure the control system.

# Machine model parameter estimates

par = InductionMachineInvGammaPars(

n_p=2, R_s=3.7, R_R=2.1, L_sgm=.021, L_M=.224)

# Set nominal values and limits for reference generation

cfg = control.CurrentReferenceCfg(

par, max_i_s=1.5*base.i, nom_u_s=base.u, nom_w_s=base.w)

# Create the control system

ctrl = control.CurrentVectorControl(par, cfg, T_s=250e-6, sensorless=True)

Set the torque reference and the actual speed.

# Torque reference steps

ctrl.ref.tau_M = lambda t: (t > .25)*nom.tau - (t > 1.25)*2*nom.tau

# Actual speed varies sinusoidally

mdl.mechanics.w_M = lambda t: .5*(base.w/base.n_p)*np.sin(2*np.pi*1*t)

Create the simulation object and simulate it.

sim = model.Simulation(mdl, ctrl)

sim.simulate(t_stop=2)

Plot results in per-unit values. By omitting the argument base you can plot the results in SI units.

plot(sim, base)

Total running time of the script: (0 minutes 4.710 seconds)