Note

Go to the end to download the full example code.

2.2-kW PMSM, 2-mass mechanics#

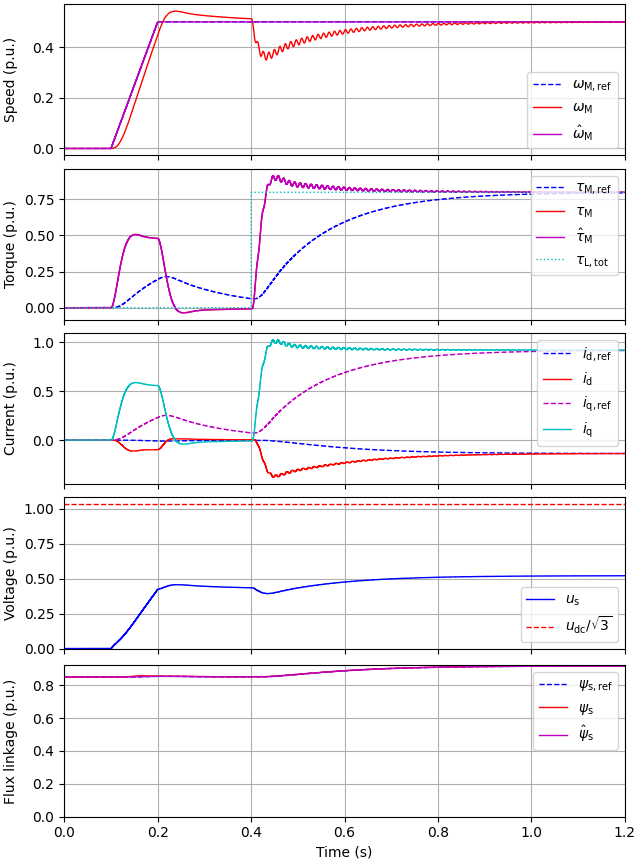

This example simulates observer-based V/Hz control of a 2.2-kW PMSM drive. The mechanical subsystem is modeled as a two-mass system. The resonance frequency of the mechanics is around 85 Hz. The mechanical parameters correspond to [1], except that the torsional damping is set to a smaller value in this example.

import matplotlib.pyplot as plt

import numpy as np

import motulator.drive.control.sm as control

from motulator.drive import model, utils

Compute base values from the nominal values.

nom = utils.NominalValues(U=370, I=4.3, f=75, P=2.2e3, tau=14)

base = utils.BaseValues.from_nominal(nom, n_p=3)

Configure the system model.

par = model.SynchronousMachinePars(n_p=3, R_s=3.6, L_d=0.036, L_q=0.051, psi_f=0.545)

machine = model.SynchronousMachine(par)

mechanics = model.TwoMassMechanicalSystem(J_M=0.005, J_L=0.005, K_S=700, C_S=0.01)

converter = model.VoltageSourceConverter(u_dc=540)

mdl = model.Drive(machine, mechanics, converter)

Configure the control system.

est_par = par # Assume accurate model parameter estimates

cfg = control.ObserverBasedVHzControllerCfg(i_s_max=1.5 * base.i)

vhz_ctrl = control.ObserverBasedVHzController(est_par, cfg)

ctrl = control.VHzControlSystem(vhz_ctrl)

Set the speed reference and the external load torque.

# Speed reference

times = np.array([0, 0.1, 0.2, 1])

values = np.array([0, 0, 1, 1]) * 0.5 * base.w_M

ctrl.set_speed_ref(utils.SequenceGenerator(times, values))

# External load torque

times = np.array([0, 0.4, 0.4, 1])

values = np.array([0, 0, 1, 1]) * nom.tau

mdl.mechanics.set_external_load_torque(utils.SequenceGenerator(times, values))

Create the simulation object, simulate, and plot the results in per-unit values.

sim = model.Simulation(mdl, ctrl)

res = sim.simulate(t_stop=1.2)

# sphinx_gallery_thumbnail_number = 3

utils.plot(res, base)

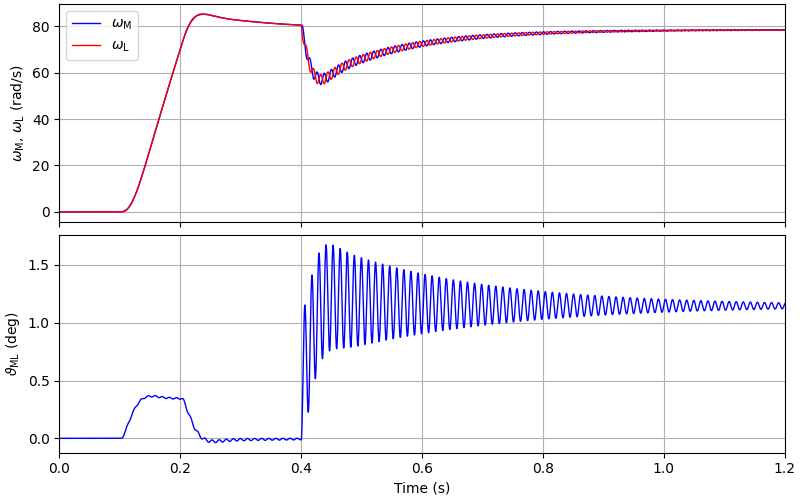

Plot the load speed and the twist angle.

t_lims = (0, 1.2)

_, (ax1, ax2) = plt.subplots(2, 1, figsize=(8, 5))

ax1.plot(res.mdl.t, res.mdl.mechanics.w_M, label=r"$\omega_\mathrm{M}$")

ax1.plot(res.mdl.t, res.mdl.mechanics.w_L, label=r"$\omega_\mathrm{L}$")

ax2.plot(res.mdl.t, res.mdl.mechanics.theta_ML * 180 / np.pi)

ax1.set_xlim(t_lims)

ax2.set_xlim(t_lims)

ax1.set_xticklabels([])

ax1.legend()

ax1.set_ylabel(r"$\omega_\mathrm{M}$, $\omega_\mathrm{L}$ (rad/s)")

ax2.set_ylabel(r"$\vartheta_\mathrm{ML}$ (deg)")

ax2.set_xlabel("Time (s)")

plt.show()

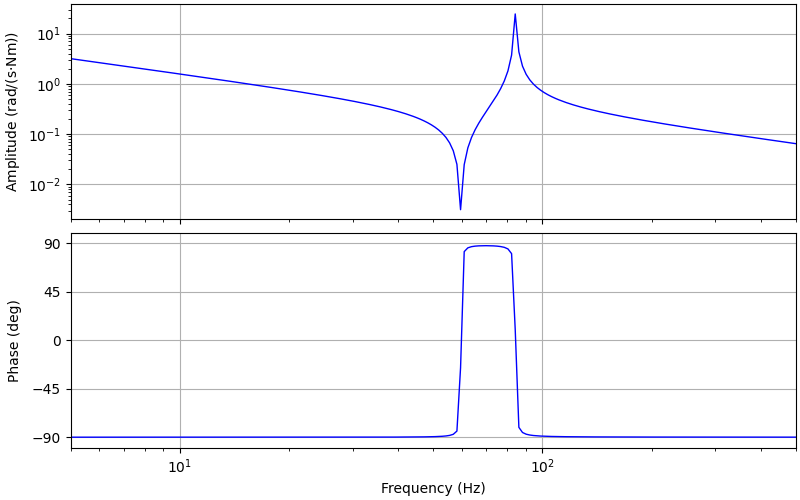

Plot the frequency response from the torque tau_M to the rotor speed w_M.

# Frequency range and number of points

f_span = (5, 500)

num = 200

# Parameters

J_M, J_L = mechanics.J_M, mechanics.J_L

K_S, C_S = mechanics.K_S, mechanics.C_S

# Frequencies

w = 2 * np.pi * np.logspace(np.log10(f_span[0]), np.log10(f_span[-1]), num=num)

s = 1j * w

# Frequency response

B = J_L * s**2 + C_S * s + K_S

A = s * (J_M * J_L * s**2 + (J_M + J_L) * C_S * s + (J_M + J_L) * K_S)

G = B / A

# Plot figure

fig, (ax1, ax2) = plt.subplots(2, 1, figsize=(8, 5))

ax1.loglog(w / (2 * np.pi), np.abs(G))

ax1.set_xticklabels([])

ax2.semilogx(w / (2 * np.pi), np.angle(G) * 180 / np.pi)

ax1.set_xlim(f_span)

ax2.set_xlim(f_span)

ax2.set_ylim([-100, 100])

ax2.set_yticks([-90, -45, 0, 45, 90])

ax1.set_ylabel(r"Amplitude (rad/(s$\cdot$Nm))")

ax2.set_ylabel("Phase (deg)")

ax2.set_xlabel("Frequency (Hz)")

fig.align_ylabels()

plt.show()

References

Total running time of the script: (0 minutes 4.094 seconds)